How Prudential Cleanroom Services Can Help Aerospace and Defense Facilities

Prudential Overall Supply has provided cleanroom services to clients in the pharmaceutical, medical device, bioscience, aerospace, and defense industries since 1960—but what is it about Prudential Cleanroom Services that benefits aerospace and defense clients across the United States? Our facilities are designed for cleanroom garment processing, and our quality management system is ISO-9001-certified. Here is a look at how aerospace/defense facilities depend on cleanrooms and how our services can help.

What Is a Cleanroom?

A cleanroom is a highly controlled, sterile environment. The level of contamination is precisely controlled, with a maximum allowable amount of particulates, , microbes, and other contaminants. Aerospace cleanrooms also require precise temperature, humidity, and pressure control, with particles down to 0.3 microns captured by a High Efficiency Particulate Air, or HEPA, filters.

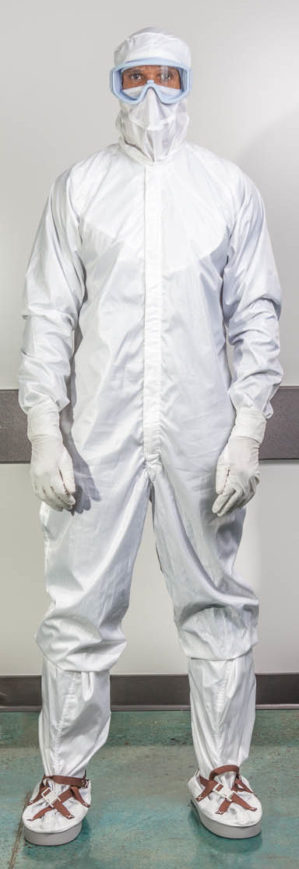

An Ultra Low Particulate Air, or ULPA, filter may be installed as well. In the highest-class cleanrooms, occupants are required to wear completely enclosed garments, including zippered body coverings, boots, and gloves, as well as full respiratory enclosures.

How Are Cleanrooms Used in Aerospace and Defense Facilities?

An aerospace facility may use a cleanroom to manufacture, assemble, and test very sensitive components and products used in aircraft and spacecraft. Cleanrooms are where some of the most intricate electronics systems and precise optical systems are developed.

A sensitive mirror, for example, installed in a space satellite may be built in a cleanroom; even the smallest speck of dust may impede the visibility of objects millions of lightyears away. Defense contractors may use cleanrooms for applications such as assembling radar systems, maintaining marine equipment such as submarine periscopes, or to support thin film deposition, vacuum coating, and other advanced processes.

In addition to protecting products, cleanrooms keep aerospace and defense workers safe. All components must be designed to prevent outgassing. Electro-static discharge materials are also often used to prevent dangerous hazards. Systems to protect equipment and workers may be installed for entry and exit, including fully sealed air showers, laminar flow systems, and other technologies to prevent contamination inside and outside the cleanroom. Sophisticated fire suppression systems may be installed as well.

Some workers at aerospace and defense companies use cleanrooms daily in the scope of their jobs. These facilities must meet ASTM, ISO, and NASA standards, among others, in regard to air filtration, procedures, and the garments worn.

How Can Prudential Cleanroom Services Help Aerospace/Defense Companies?

Prudential Overall Supply provides the leading cleanroom garment processing service in the industry. Whether your environment is aseptic, particulate, or ESD-controlled or a combination of these, we can ensure sterile garment processing every time. Companies that rely on our services include those in the semiconductor, medical device, and aircraft production industries.

We also supply different types of cleanroom uniforms and apparel for the most sterile applications, as well as reusable cleanroom supplies such as mops and goggles. To learn more, browse our online inventory or call 800-767-5536. A representative can answer your questions and help find the cleanroom services you need.