“Friends of Phoenix”: Prudential Plant Certified as VPP ‘Star’

The soulful strains of a mariachi band combined with the roar of applause during at a recent ceremony in which the Arizona Department of Occupational Health and Safety (ADOSH) recognized Prudential Overall Supply’s plant in Phoenix as a Voluntary Protection Program (VPP) “Star” site.

One staff member at the awards program on June 20 laughed, noting that at the start of the VPP certification process, Prudential managers had told staff that if the Phoenix plant could attain the prestigious VPP Star status, they’d hire a mariachi band to help them celebrate.

“Safety is no accident,” said plant manager Mark Rasmussen, addressing the crowd of nearly 150 people gathered at the Phoenix plant for a ceremony honoring Prudential’s VPP recognition. “And our safety journey doesn’t stop here; this is just the beginning,” he added.

BUILDING AWARENESS

The VPP Star process began over two years ago. Achieving the highest recognition available for safety from ADOSH took the combined efforts of the corporate office, local managers, agency representatives and—most importantly—the 77 employees who work at the Phoenix plant. “We realized we had a problem when we looked at the attendance and injuries, said Tom Watts, president of Prudential, to the crowd of employees, ADOSH officials, customers and guests. “Getting VPP-certified was the right thing to do. We want to send people home in the same condition they came to work.”

Obtaining status as a VPP-certified facility isn’t easy. It requires applications, inspections, new-employee training sessions across all fields, and the implementation of new safety features and procedures. Yet, the team at Prudential was determined. And after more than two years’ effort, they’ve earned the coveted ‘Star’ status. “We took management out of the picture,” Watts said. “It was difficult for us to stand aside, but we realized that the local people, the managers and floor employees themselves could take control, take responsibility and take the process on.”

None of this could have happened without the support, participation and determination of each employee. “At the end of the day, it’s all about the employees,” said safety coordinator Aaron Elberson. “To me, the most touching part of the ceremony was when Maria got up and made her speech in Spanish. It shows that they all know and they all care; it’s not just a façade.”

Maria Barrajas, part of the CHAMPS (Changing Habits and Making People Safe) committee, was one of the three committee members who spoke during the ceremony. “Before VPP, it seemed like nobody was concerned with safety, and most employees weren’t actively involved,” she said in her native Spanish. “Since we began VPP, we learned how to change our safety habits. I am more conscious about my safety today, even in my personal life.”

INCIDENT RATE PROGRESS

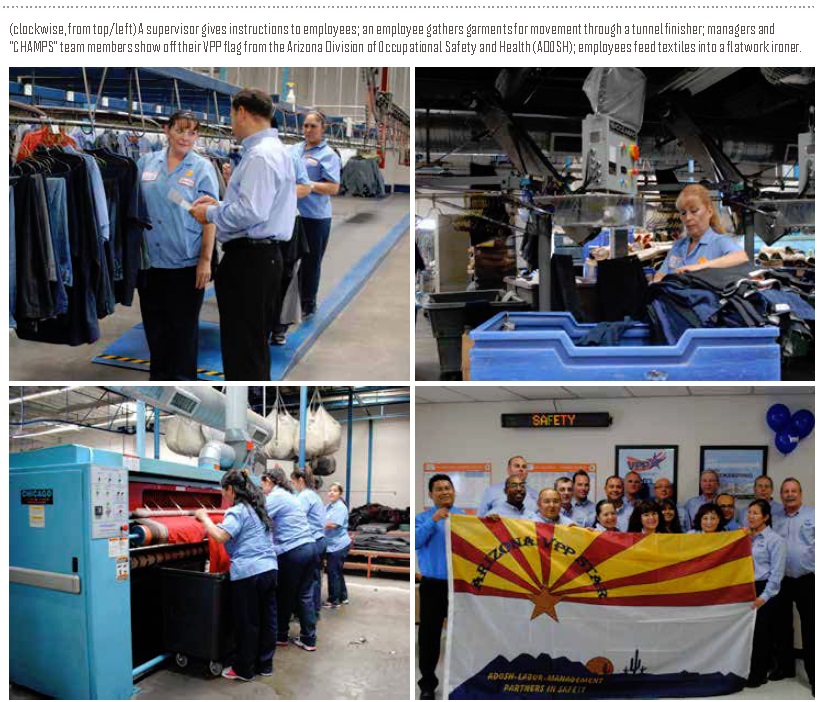

CHAMPS is an employee-driven group of volunteers dedicated to educating and training employees to work safely. Instead of safety notices e-mailed or posted by management, CHAMPS encourages the employees themselves o implement their own safety features, to discuss new ideas for improving their work environment, and to address and mitigate all safety concerns. Under CHAMPS, there are five employee-run subcommittees. Each one focuses on a different aspect of safety such as ergonomics and fire and safety. The committees work together to ensure safer conditions through training and awareness.

Rasmussen congratulated them, “The real heroes are the CHAMPS. What a phenomenal job they’ve done.”

“It’s employee driven,” said Stephanie Leibick, marketing manager for Prudential. “They’re the most important part of the whole process.” And that’s why, of Prudential’s 15 plants and 10 service centers, Phoenix was chosen. Even before the start of the VPP process, Phoenix already had a lower-than-average TCIR (Total Case Incident Rate), and the employees and managers were a solid team. Now two years later, after applying new safety programs and limiting hazards, the facility is 70% below the industry average.

EMPLOYEES STEP UP

On a tour of the facility, staff members proudly pointed out many of the improved safety features installed, such as anti-fatigue floor mats, yellow warning labels on obtrusive objects, metal guards covering moving parts, easy-access emergency shut-off switches and floor-to-ceiling poles painted in red to show the location of every fire extinguisher in the plant.

As part of the certification process, ADOSH officials interviewed more that 40 employees, and according to the agency’s report, every interviewee was comfortable answering questions, and reported that they felt safe in their work environment.

“What’s really the big issue is how we can work together to mitigate problems and make everything safer,” said Jessie Atencio, assistant director of ADOSH. The agency’s report said that overall, employees seemed content with management involvement: they were visible during all aspects of the workday, but not overbearing, creating an environment where everyone felt comfortable working together. “Prudential has created a work culture of safety where everyone goes home safe. We appreciate the hard work that everyone has done. It’s all a result of the employees’ hard work,” added ADOSH representative William Warren.

During the ceremony, two other plant employees also shared their experiences with the VPP process. “It allows us to be more aware of our surroundings,” said Jason Bogar. “It’s all about the leadership and confidence you see in people as they step out of their comfort zones to speak at the meetings and learn to do new things.” Co-worker Alejandro Mota added, “At first, I wasn’t really involved at all. As time progressed with training, I learned how to do safety audits, JSAs, and (make) recommendations. When the time came to train other employees, I felt up to the task, and confident in the training I’d received.”

The ceremony concluded with Atencio presenting a commemorative flag to the employees. “The flag literally embodies what you’ve done, and all of your accomplishments,” he said, handing the flag to the members of CHAMPS. A framed award also was presented to Watts; every employee had signed it. The city of Phoenix also recognized Prudential with the “Friends of Phoenix Award,” on behalf of all they’ve done to make Prudential a safer working environment.

Watts offered his thanks at the conclusion of the ceremony, “I want to congratulate all employees in Phoenix for working safely. Todos los empleados, muchas gracias,” he added in Spanish. “We’ve come a long way.”

Release date: 08/08/2013

Contact: Jerry Martin, V.P. of Sales & Marketing (949) 996-8976

Source: TRSA Magazine, August 2013 Issue

By: Dawn Rainbolt, Intern Writer for Textile Services